Dispositivi di stampa personalizzabili per le vostre esigenze industriali uniche

| Attributo |

Valore |

| Materiale |

di alluminio, inossidabile, acciaio, ottone |

| Colore |

Personalizzabile |

| Tolleranza |

0.1 mm |

| Finisci. |

Rivestimento in polvere |

| Applicazione |

Automotive, elettronica, mobili |

| Processo di produzione |

Stampatura, taglio, piegatura |

| Spessore |

1.5 mm |

| Costo |

A prezzi accessibili |

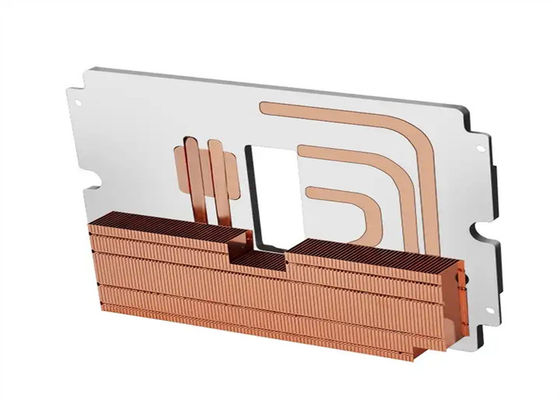

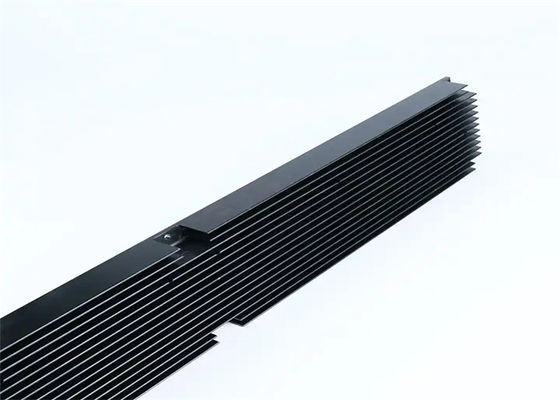

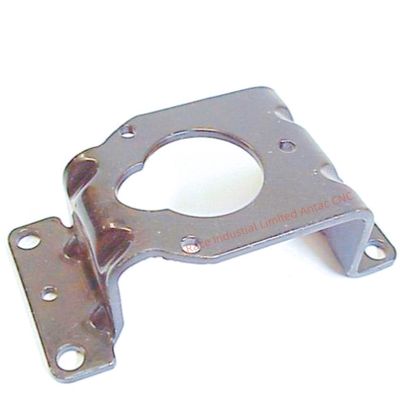

Nel moderno sistema industriale, stampare la lamiera è come un costruttore invisibile.Prende lamiere metalliche sottili come materie prime e modella varie parti attraverso una serie di precisi processi di lavorazione a freddoLa produzione di lamiere di metallo di spessore inferiore a 6 mm, grazie a processi combinati quali taglio, perforazione, piegatura,e saldatura, realizza la caratteristica di spessore uniforme della stessa parte.

Base tecnica: trasformazione precisa dalle materie prime ai prodotti finiti

Logica di processo rigorosa

Il processo di lavorazione della lamiera di stampaggio è la ricerca definitiva di precisione. dal taglio della piastra al foraggio CNC, taglio laser, piegatura e saldatura finale o rivettazione,ogni fase garantisce la consistenza del prodottoPer esempio, nella produzione di pannelli di portiere di automobili, ogni passo dalla piastra piatta alla parte formata richiede un controllo preciso attraverso dozzine di processi.

Coordinamento delle attrezzature

Questo processo è supportato da un sistema completo di attrezzature, tra cui macchine da taglio, macchine da foratura CNC, macchine da taglio laser, macchine da piegatura e attrezzature ausiliarie come decollatori, livellatori,e macchine per la depurazioneQuesti sono collegati attraverso sistemi di controllo digitale, consentendo la produzione di centinaia di parti standard all'ora.

Controllo della qualità

Il controllo della qualità si svolge durante l'intero processo con analisi spettrale delle materie prime, monitoraggio dimensionale online, rilevamento difetti ad ultrasuoni,e rigorose ispezioni dei prodotti finiti, comprese le prove di salino e di caricoCiò garantisce un tasso di qualificazione stabile superiore al 99%.

Selezione del materiale: adattarsi a diversi scenari

Materiali orientati alla funzione

Scenari diversi richiedono soluzioni materiali diverse: SPCC per parti strutturali semplici, SECC per involucri elettronici, SGCC per strutture esterne,e acciaio inossidabile SUS304 per apparecchiature mediche a causa della sua resistenza alla corrosione.

Compatibilità materiale-processo

La selezione del materiale deve corrispondere alla tecnologia di lavorazione.SUS304 ha prestazioni di saldatura eccellenti, ma richiede tempi di timbrazione controllati a causa di indurimento del lavoro.

Processi di produzione

- Taglio laser CNC

- Perforazione della torretta CNC

- Pressione/piegatura del freno CNC

- Macchine per la lavorazione a CNC (moldatura e tornitura)

- Saldatura di acciaio al carbonio, acciaio inossidabile, alluminio

- Pressione e stampaggio dei metalli

- Guillotinazione/tesiatura in metallo

- Segatura a fascia

- Piegamento di tubi

- Assemblaggio e imballaggio del prodotto

Specialità materiali

- Acciaio inossidabile

- Acciaio galvanizzato

- Acciaio di ferro nero

- Aluminici

Capacità di progettazione e ingegneria

Utilizziamo la progettazione CAD e la stima computerizzata per garantire l'efficienza del sistema e proiezioni di costi accurate.I nostri Project Manager interni effettuano revisioni dettagliate dei piani utilizzando software di modellazione 3D per rilevare potenziali conflitti e garantire finiture di alta qualità e installazione efficiente del progetto.

Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!  Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!